Heart Shape Diamond Pink Color Cubic Zirconia Rhodium Over Sterling Silver Ring

Heart Shape Center Diamond Pink CZ Rhodium Over Sterling Silver Ring

1. Jewelry Designing

The art of designing jewelry is inspired by many emotions; the desire for beauty, the need for acceptance, the urge to impress or to show commitment. The need to express reverence, loyalty or remembrance, have driven jewelry designers to dream since the beginning of time.

2. CAD Designing

Once created by hand drawing, CAD jewelry designs are developed on computer screens and software that metamorphose their thoughts and keystrokes into works of art. These works are then sent in the form of digital files to mills, printers, or growing machines where they will be transformed from data to a 3-D wax or resin form.

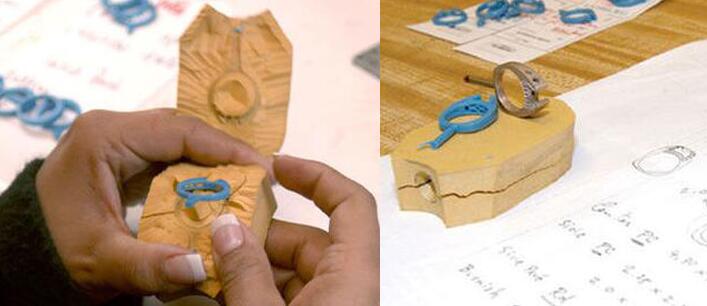

3. Wax Injection

Automatically Injection for the wax from the rubber or resin mold.

4. Stone Wax Setting

We set all kinds of small CZ on the wax.

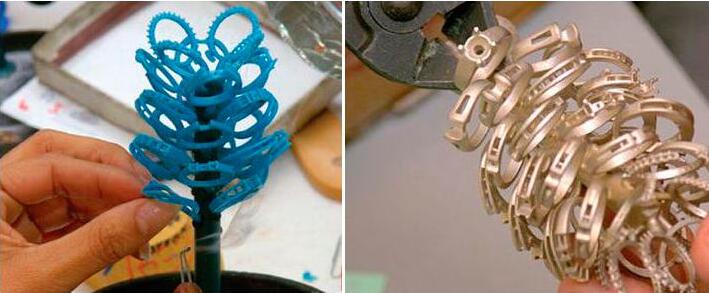

5. Jewelry Casting

Wax models are connected to one another on a sprue to form a tree-like configuration. The alignment of the models is arranged to allow platinum to flow through the “tree” with minimum turbulence or resistance.

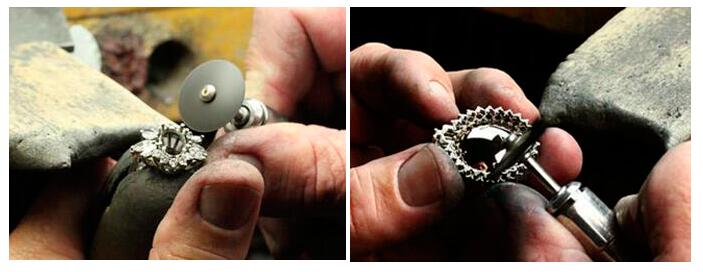

6. Stone Hand Setting

Hand setting is more suitable for Main stones.

7. Polishing

No matter what type of jewelry it is, It needs to be high polished to keep clean and shiny.

8. Plating

It is rhodium plating that lends the shimmering silver tone to metal. When created, white gold jewelry has a faint tint of yellow. To compensate for this, it is coated with rhodium plating. Since rhodium is a rare precious metal that is extremely hard and corrosion resistant, it holds a brilliant polish and provides a durable finish on fine jewelry.

9.Quality Control

Quality control is a process that is used to ensure a certain level of quality for every piece of jewelry. Eton engages in quality control typically have a team of workers who focus on all the procedures of the jewelry production.

Heart Shape Center Diamond Pink CZ Rhodium Over Sterling Silver Ring

Trangle Cut created Tanzanite CZ rhodium Over Sterling design engagement ring

3 Ct 8 Heart 8 Arrow White AAA Cubic Zirconia Main Stone Cocktail Engagement Wedding Rings

925 Sterling Silver Solitaire AAA Yellow Cubic Zirconia Twist Criss Cross Infinity Engagement ring

Sterling Silver Eternity Necklace with Rainbow Synthetic Sapphire gemstone

925 Sterling Silver White Gold Flash-plated Baguette Colorful CZ Cubic Zirconia Cuff Bangle

online service